Date published: April 25, 2024

Enhancing Inspections with Advanced Imaging and AI in Industry 4.0

Today, industrial efficiency and quality are the number one priority – hence, the need for inspection.

#Industry4.0, an era of digital transformation and automation, has changed the course of inspection. The integration of thermal imaging, X-ray, UV, drones, and artificial intelligence (#AI) is setting new benchmarks for accuracy and operational excellence. These innovations not only enhance the detection of anomalies and defects but also substantially improve safety and cost-efficiency across various sectors.

While humans usually perform inspections, limitations, subjectivity, and potential human errors have led to inconsistencies in identifying defects.

In Industry 4.0, machine vision inspection has become crucial to ensure efficiency while minimizing downtime. Its benefits and use cases are undeniable, but let’s take a closer look together.

Advanced Imaging Techniques and Their Applications

Many businesses have already adopted advanced imaging techniques, such as thermal, X-ray, and UV imaging. And for a good reason – these technologies provide deep insights into the assets’ condition and performance, offer defect detection, predict maintenance schedules, and enhance safety.

Thermal Imaging: Thermal imaging helps detect hot spots, overheating components, and energy inefficiencies in machinery and electrical systems without the need for human physical contact.

X-ray: X-ray imaging also provides detailed insights into the internal structure of components and assemblies – detecting cracks, voids, and other defects in metal castings, welds, and composite materials.

UV Imaging: UV imaging identifies electrical discharges and corona effects, perfect for inspecting high-voltage equipment such as transformers, circuit breakers, and transmission lines.

The Role of Drones in Conducting Inspections

Drones equipped with advanced imaging technologies have taken inspections to new heights (literally). With a compound annual growth rate of over 20%, the global market for drones is growing faster than ever, making it a viable tool for monitoring and inspections in different industries.

These are just some of the reasons why drones are the preferred choice:

- Accessibility to challenging locations – Drones can easily reach high-altitude structures, expansive infrastructure like solar farms, and other inaccessible areas, eliminating the need for direct human interaction.

- Safety – Using drones for inspections significantly reduces the risk to human inspectors, especially in dangerous environments.

- Efficiency – Drones can cut down the time and manpower required, offering faster, more frequent, and more thorough inspections.

- Cost reduction – Industries leveraging drones and AI for inspections have reported reductions in inspection costs by up to 50% in some cases. This is all due to the decreased need for manual labor, less downtime, and early detection of potential issues before they become costly repairs.

- Data collection – With advanced imaging technologies, drones can capture high-resolution photographs, thermal images, and videos, providing detailed insights that might not be visible or accessible during manual inspections.

How AI Enhances the Accuracy and Efficiency of Defect Detection

Imaging techniques can indeed speed up operational processes and cut down costs by collecting high-resolution photos and videos of inspection sites, but how can operation managers further organize and automate this information? AI is another technology of Industry 4.0 that can help detect defects.

How does it work?

Imaging devices capture footage, typically images or videos using sensors or cameras placed on site. These visuals are then collected and transmitted into an AI system that analyzes the data using deep learning models and extracts key features and patterns (for instance, objects, products, processes, and anomalies). Then, AI compares the obtained data to predefined (or trained) standards and classifies the obtained visuals, identifies defects, and even recommends preventive measures with remarkable accuracy.

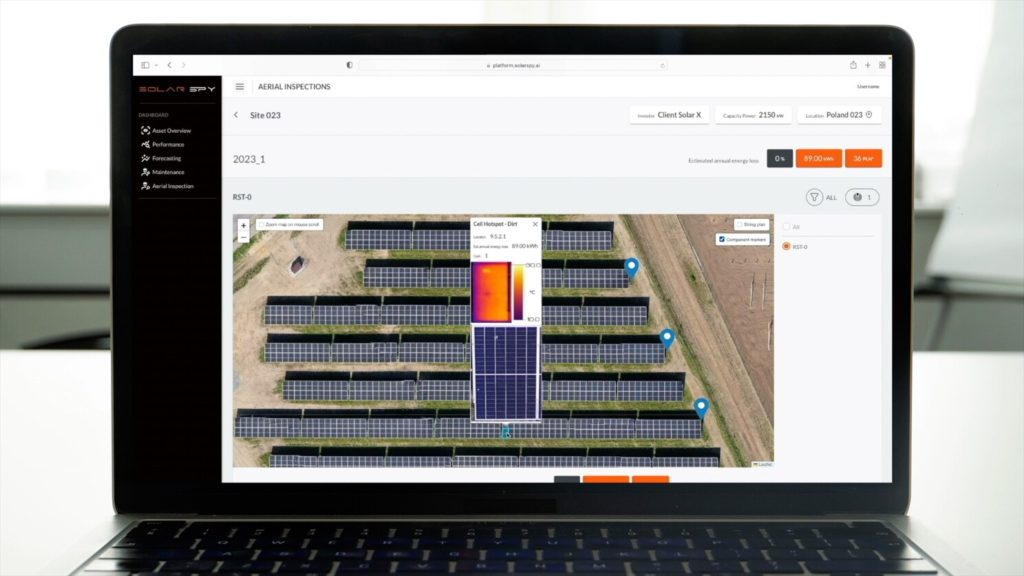

Solar Spy: Pragmile’s AI Case Study

As most of our readers are already well-aware, Pragmile AI’s solutions are aimed at helping businesses automate their daily tasks and speed up their processes. With that goal in mind, Pragmile created the foundational technology for SOLAR SPY, a SaaS platform that uses imaging techniques (thermal imaging, high-definition RGB imaging), drones, and AI to monitor, detect anomalies, and optimize the performance of PV (photovoltaic system) installations, helping businesses optimize their solar investments and the management thereof.

By employing the mix of imaging techniques and AI, Solar Spy has achieved the following:

- Clients recover on average 5% (and, in some cases, up to 18%) of lost revenue by addressing cell-level anomalies identified by Solar Spy’s services.

- The use of drones to capture high-resolution images reduces the need for manual inspections, reducing time and costs.

- Solar Spy’s AI is trained on vast datasets to detect a wide range of anomalies and defects, such as hot spots, cracks, delamination, and soiling. The integration with Solar Spy’s PV Copilot platform offers clients a digital twin of their solar assets for effective monitoring and maintenance planning.

A single person can oversee a complete PV portfolio, thanks to automated monitoring and analysis processes.

Benefits of Combining Advanced Imaging, Drones, and AI for Inspections

Advanced imaging and drones by themselves offer powerful solutions for inspections, automating manual labor, eliminating the need for manual access to difficult locations, and speeding the process of anomaly detection. However, coupled with AI, these technologies are empowering companies to transition from reactive to predictive maintenance strategies, optimizing asset longevity and performance.

The combination of these technologies offers several advantages, including:

- Increased accuracy and speed – AI-powered analysis of images captured by drones reduces human error and speeds up the inspection process.

- Enhanced safety – Drones eliminate the need for human inspectors to access dangerous or hard-to-reach areas.

- Cost efficiency – Faster inspections and early detection of issues translate into cost savings by preventing extensive damages and downtime.

- Data-driven decisions – The insights provided by AI enable businesses to make informed decisions regarding maintenance and operations.

Conclusion

Advanced imaging, drones, and AI in industrial inspections have been revolutionizing Industry 4.0. The future looks even more promising with the adoption of the Internet of Things (IoT), augmenting the capabilities and outcomes of industrial inspections. We’ll take a closer look at the IoT aspect of inspection further in our blog series. Stay tuned!

Contact Marcin Jabłonowski directly and let’s implement an AI solution to transform the way you do business.

Schedule a free consultation with

our AI and technology experts

Take advantage of the latest AI solutions, tailored to your company's needs. Book a consultation with AI solution architects at Pragmile and discover new opportunities in energy management.

Please, provide your business email to schedule a meeting